Very economical

neodymium magnet motors

Scientist behind the technology

neodine magnet motors with

97%

efficiency

Exclusive opportunity to purchase

neodymium magnet motor technology

to start produce under your brand

high economical motors

Low power neodymium magnet motors

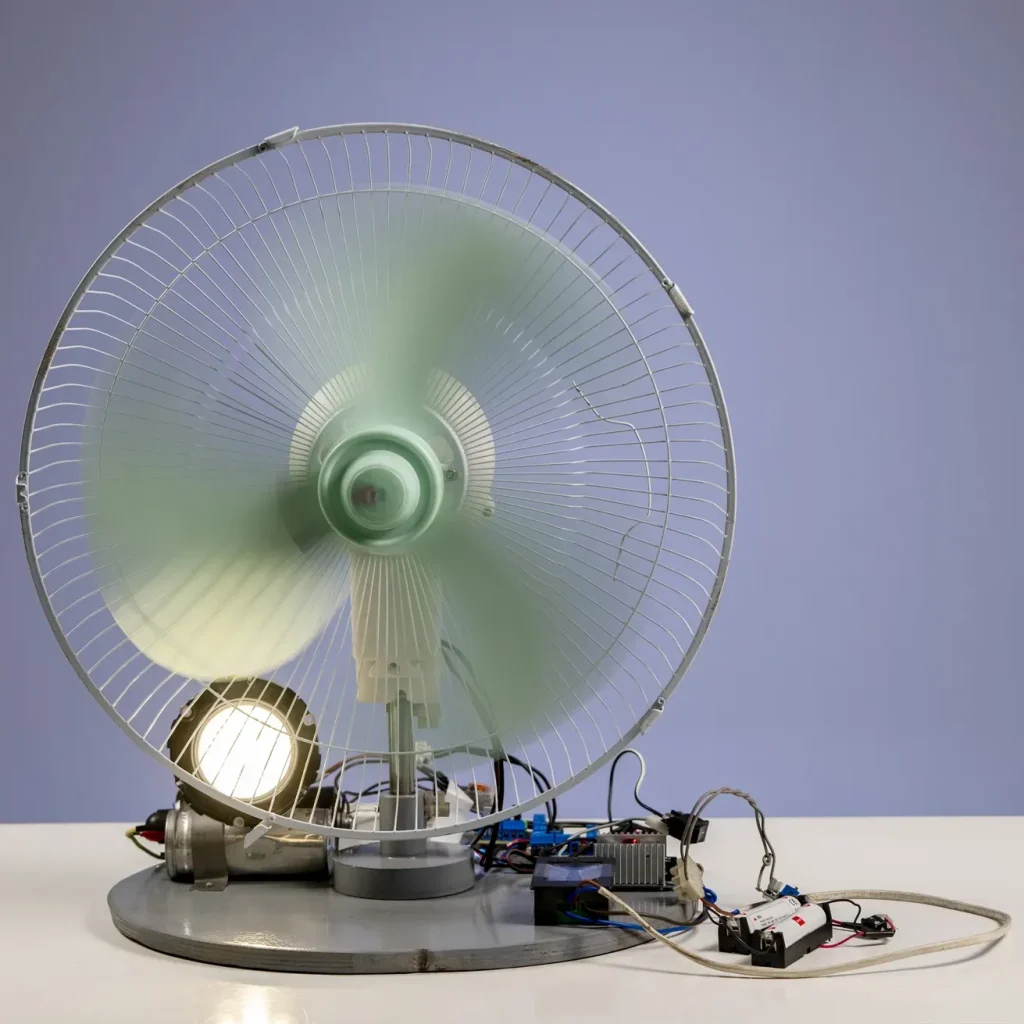

Low power motor 3,8W V3

This updated prototype is ready for production or to be integrated in your system.

Our team has found a way to recover electrical energy that is wasted in heating (EDS) in a conventional engine. Thanks to our solution, our electric motor does not heat up, and we are able to redirect this energy to other devices. For example: for a light source or for charging a battery. It is also possible, with the help of additional batteries, to accumulate excess energy that can be used to operate this fan.

Power: 3,8W

Current: AC/DC

Rotational speed: 966rpm

Dimmable: 0-1100 rpm

Voltage: 7,2V

Blade diameter: ∅35cm

Development stage: Ready for production

Power source: Batteries or AC adapter

Standstill torque: 0.48 Nm on 1000rpm and 3,8w consumption

Presentation video

Low power motor 5W V2

The second prototype is already built in a closed case and works on batteries. The model is ready for production.

Power: 5W

Current: AC/DC

Rotational speed: 966rpm

Dimmable: 0-1100 rpm

Voltage: 15V

Blade diameter: ∅35cm

Development stage: Ready for production

Power source: Batteries or AC adapter

Standstill torque: 0.48 Nm on 1000rpm and 5w consumption

Model comparison video

Low power motor 5W V1

The first prototype designed to demonstrate energy efficiency. The housing is transparent to see the operation of the engine and the parts used.

Power: 5W

Current: AC/DC

Rotational speed: 966rpm

Dimmable: 0-1100 rpm

Voltage: 15V

Blade diameter: ∅35cm

Development stage: Prototype

Power source: Batteries or AC adapter

Model comparison video

High power 2kw neodymium magnet motors

These technologies developed cooperating with Global Engineering Baltia

Production timeline video of industrial motor generator

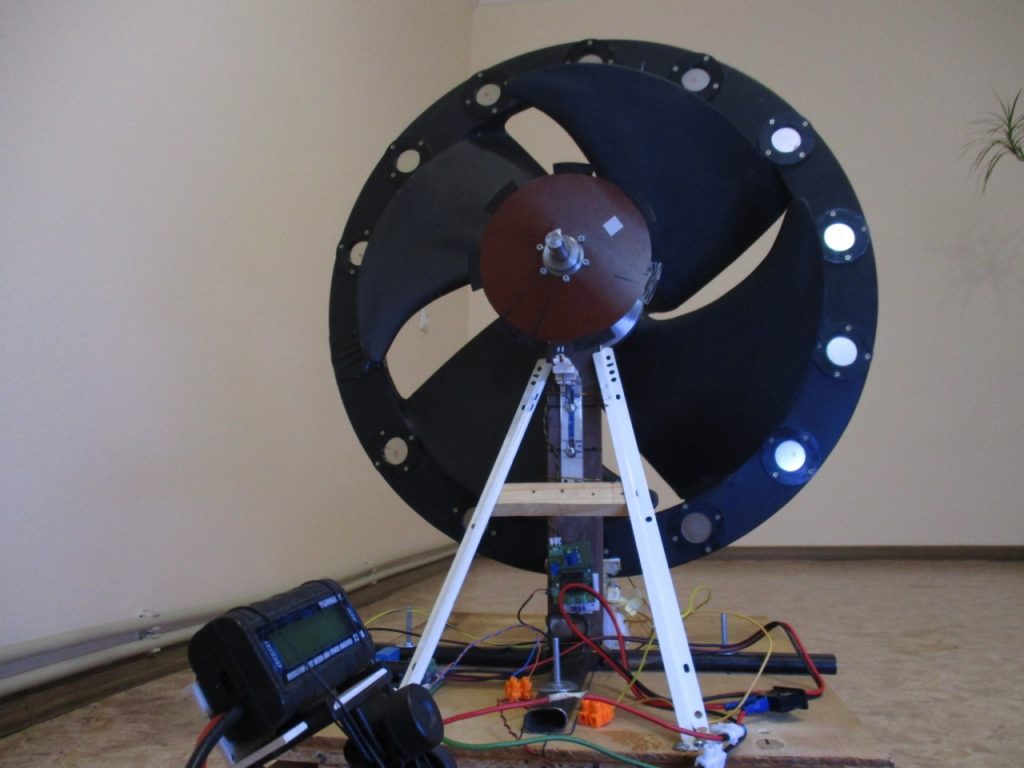

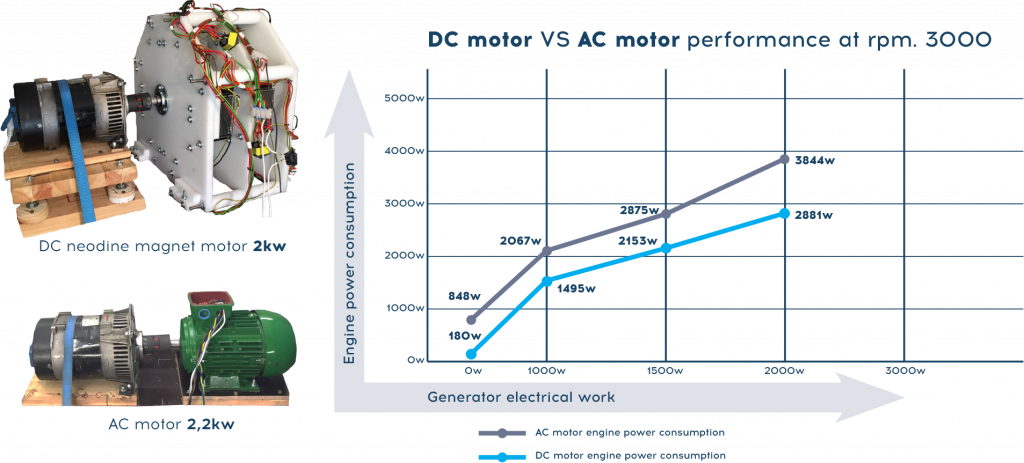

High power motor 2kw V1

The first prototype designed to demonstrate energy efficiency. The housing is transparent to see the operation of the engine, the parts used and to easy assemble.

Power: 2kw

Current: AC/DC

Rotational speed: 3000rpm

Powered: 350v batteries or 220v AC

Development stage: Prototype

Standstill torque: 6.3 Nm on 3000rpm and 2.2kw consumption

Development stages, laboratory testing and real life performance

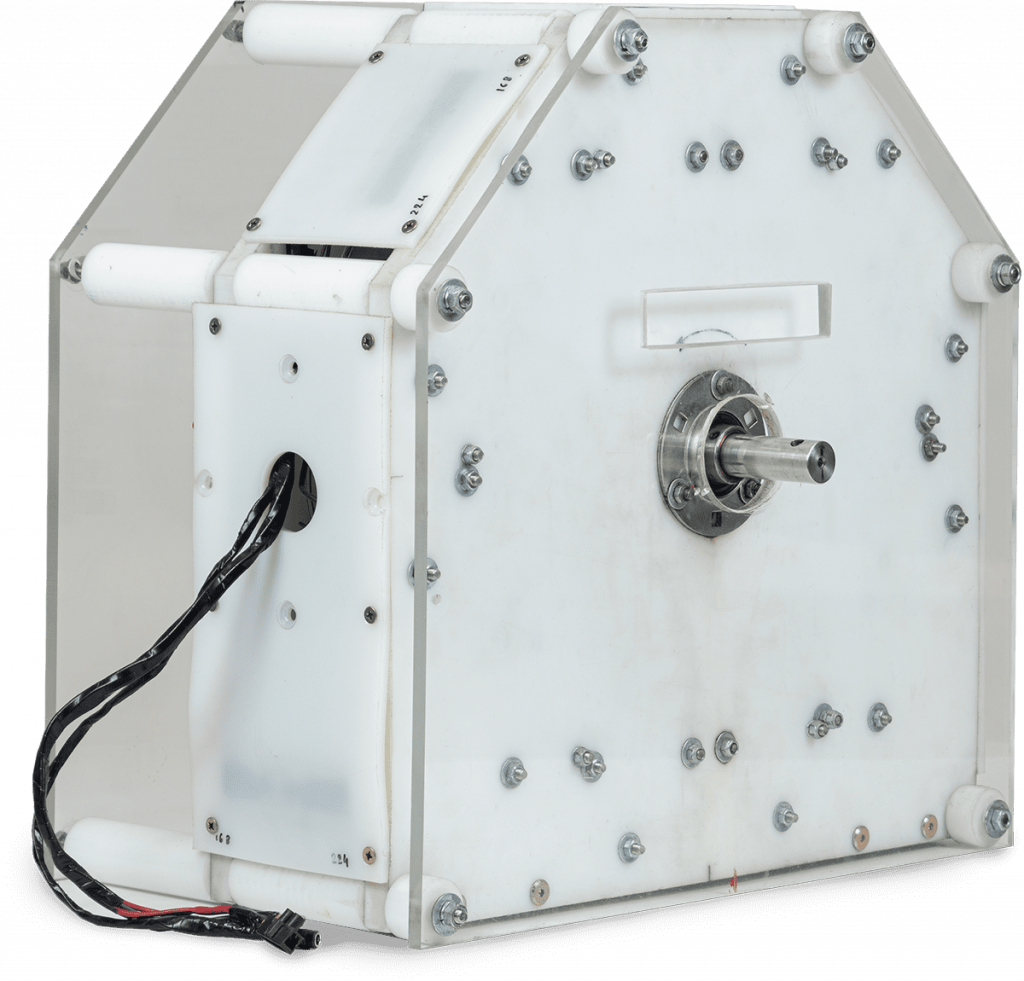

High power motor 2kw V2

The second prototype has already been created in a closed housing. The model is ready for production.

Power: 2kw

Current: AC/DC

Rotational speed: 3000-5000rpm

Powered: 350-400v batteries or 220v AC

Development stage: Industrial prototype

Standstill torque: 6.3 Nm on 3000rpm and 2.2kw consumption

Development stages, laboratory testing and real life performance

Full report of motor performance from Riga Technical University

Short summary of tests

The tested device (motor with permanent magnets) achieves the maximum efficiency factor 0.95 +/- 1.5% (min. value: 0.94, max. value: 0.97), that corresponds to class IE4. The optimum operation of the motor (within the range of the tested power and rotation frequency determined by the customer) is achieved at mechanical power 2272W.

During the testing the temperature of the device did not exceed 27°C.

Point of the optimal operation of the device is determined: at Pm = 2272W and n=3000rev/min.

| DPM | EI1 class | EI2 class | EI3 class | EI4 class | |

| Efficiency factor | 0.95 | 0.80 | 0.83 | 0.86 | 0.88 |

| Mechanical power, W | 2272 | 2200 | 2200 | 2200 | 2200 |

| Electric power, W | 2387 | 2750 | 2650 | 2558 | 2500 |

| Economy, W | – | 363 | 263 | 171 | 113 |

| Economy% | – | 13.2% | 9.9% | 6.6% | 4.5% |

Frequently asked Questions

Highly efficient engine, which uses the principle of electromagnetic resonance to optimize its efficiency.

It consumes 10-25% less electricity than ordinary motors and has a 97% efficiency factor. Can work for a long time in overload mode without heating or breaking. Capable of running up to 8,000 rpm. Without changing the construction.

10-25% lower electricity bills are obtained.

Yes, contact us info@jerzinlab.com

we will show real time measurements and you can take your own measurements and check out the performance.

Contact us

If you are interested in producing such economical engines, please contact us.